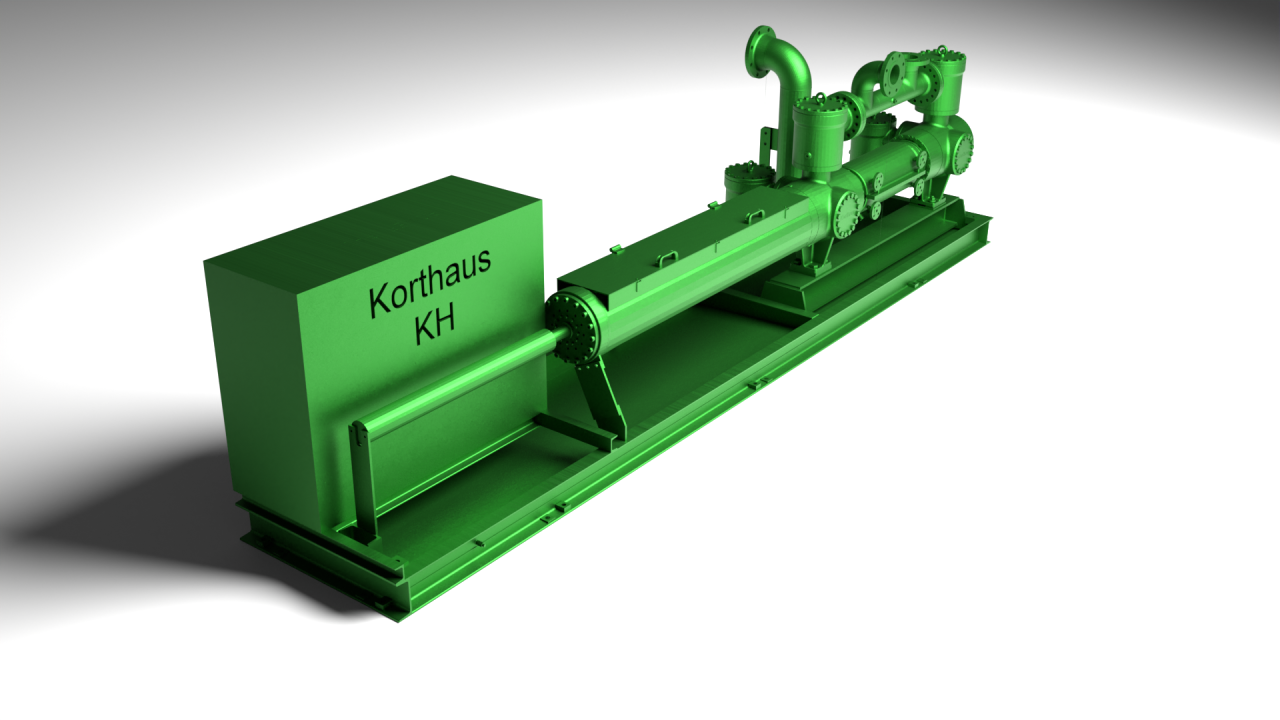

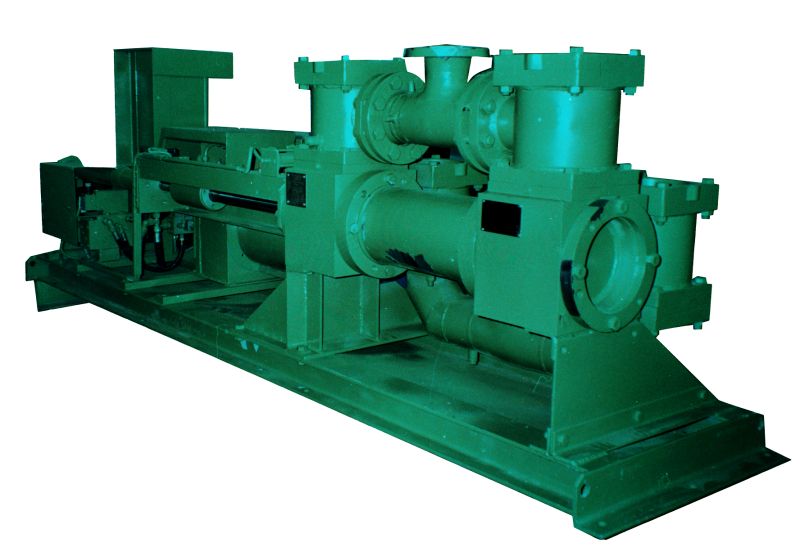

High Density Slurry Pumps Series KH

KH SLURRYPUMPS from KORTHAUS are hydraulically driven piston pumps for highly complex media in the waste disposal industry and petrochemicals. Patented control technology enables the pumping of liquid and solid mixtures.

PDF Brochure KORTHAUS piston pumps

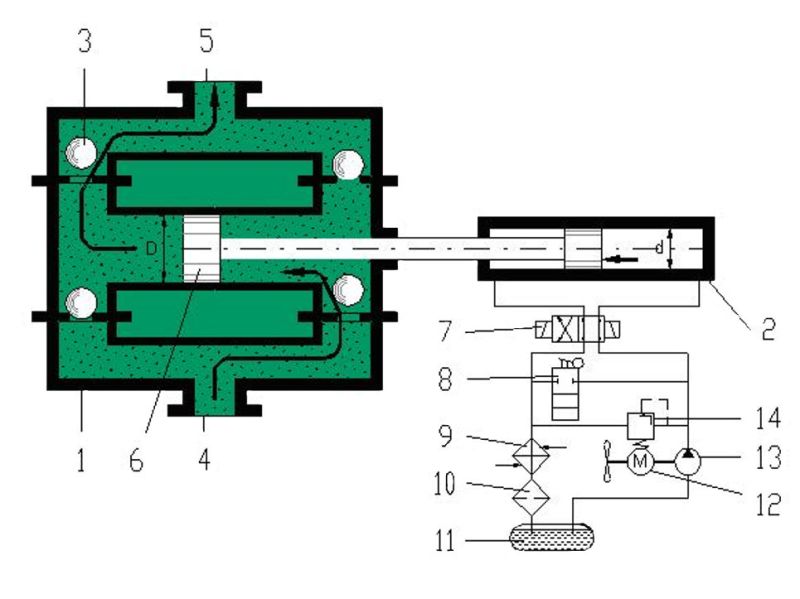

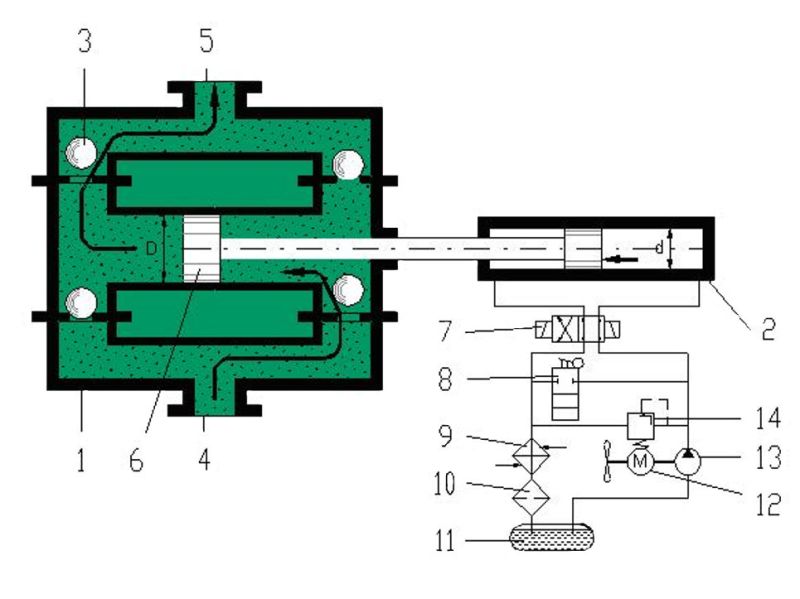

Principle of operation

- 1. pump housing

- 2. hydraulic cylinder

- 3. delivery valves

- 4. suction nozzle

- 5. discharge nozzle

- 6. piston rod

- 7. control valve

- 8. start-stop-valve

- 9. cooler

- 10. filter

- 11. tank

- 12. motor

- 13. hydraulic pump

- 14. pressure relief valve

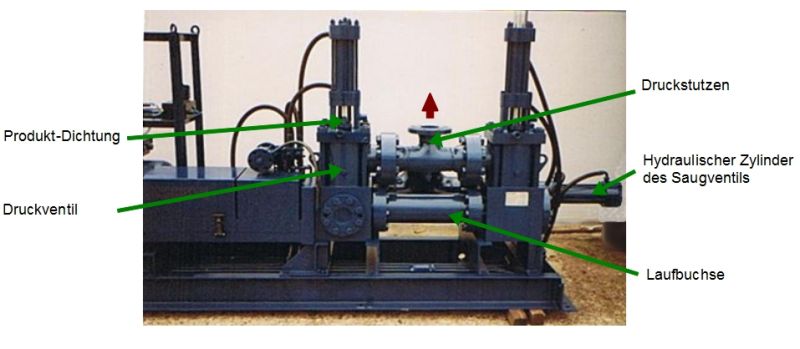

Piston pumps belong to the group of oscillating displacement pumps, here with a hydraulic control unit. A hydraulic pump (13) drives a hydraulic cylinder (7). The KORTHAUS reversing block guarantees a smooth reversal of the end loads. The pump piston (6) is attached to the cylinder rod and pumps on the slurry side. The delivery valves (3) are designed as automatic check valves or as positively switched poppet valves with hydraulic cylinder drive. The start-stop valve can be used to stop the pump while the engine is running. The pressure relief valve (14) simultaneously protects the hydraulic side and the slurry side. The hydraulic circuit is hermetically sealed and insensitive to dusty environments.

Why KORTHAUS?

- suitable for abrasive solids, liquids, flotates and gases

- pressure up to 250 bar

- maximum flow rates up to 700 m³/h

- suitable for the most extreme applications due to hermetically sealed conveying area

- self-cleaning effect of the machine in case of solids in the material to be conveyed

- no sedimentation inside the machine

- suitable for dry running

Design Features

- Ball valves or positively switched poppet valves

- Sealing via patented self-adjusting sealing systems

- Liner and piston rod with wear-resistant hard chrome as standard

Design variants

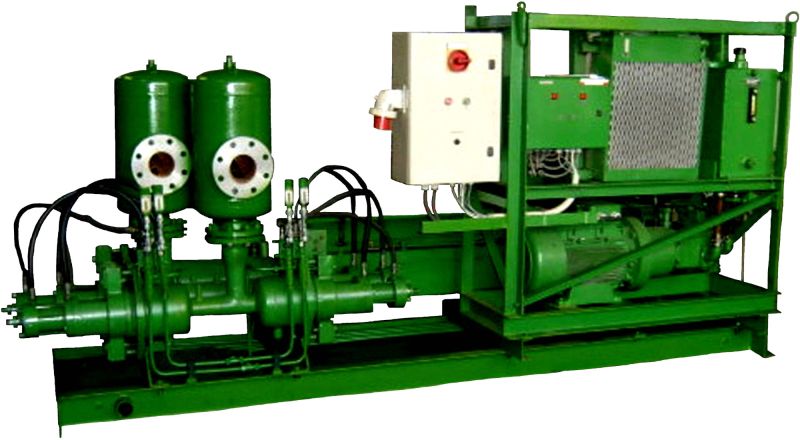

Slurry Pump Type KH-V

- Pressures up to 64 bar

- flow rates up to 240 m³/h

- large grain passages

- suitable for liquids and slurries

- NPSH ~ 1m

Kompressor Pump Type KH-F

- Pressures up to 25 bar (40 bar)

- Flow rate up to 700 m³/h

- suction with dry machine up to 8m vacuum

- suitable for thick materials, liquids, flotates and gases

- hydraulically driven valves with medium grain passages

Plunger Pump Type KH-P

- Flow rates up to 30 m³/h

- pressures up to 250 bar

- suitable for highly abrasive media (filter cakes, liquids)

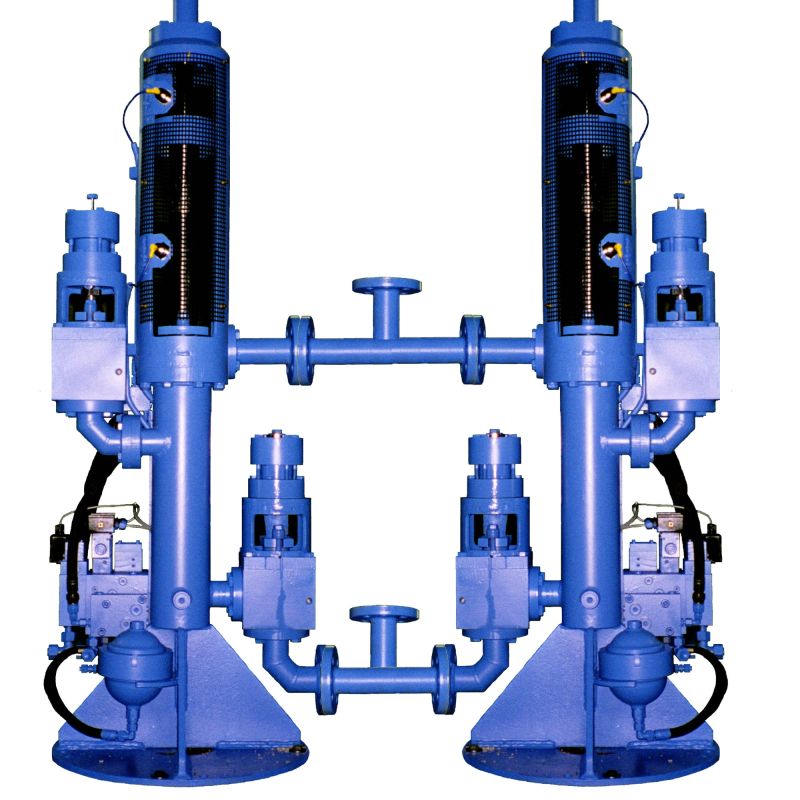

Double-Plunger Pump Type DB

- Flow rates up to 240 m³/h

- pressures up to 250 bar

- suitable for highly abrasive media (filter cakes, liquids)

- processing of medium grain sizes